We recommend BOGE, so you can rely on their efficiency and quality range of rotary screw air compressors and parts. With offices in Brisbane and Sydney, we support you locally with BOGE air systems audit, supply, installation, regular servicing, and parts. With BOGE air compressors, you can rely on your operations running on time, and every time.

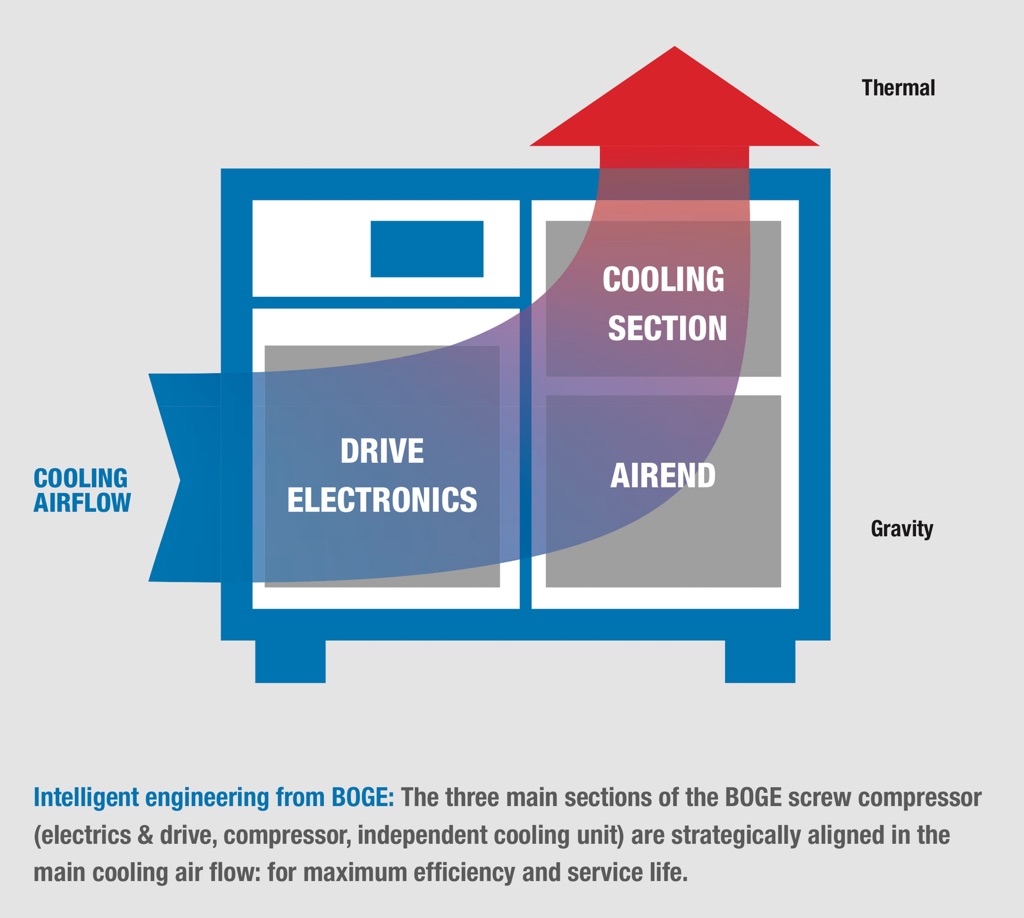

Three main sections of the BOGE screw compressor (electrics & drive, compressor, and independent cooling unit) are aligned strategically for cooling the main air flow. This maximises efficiency and service life.

The design of the BOGE screw compressor is based on nature’s laws that warm air rises, and nature does not waste energy. With high outputs, effective oil separation, and an extremely long service life of the BOGE compressor’s component parts, optimal energy consumption and reduced energy costs are assured.

BOGE designers applied this natural law to support the high efficiency of BOGE screw compressors. Air is taken in at the lowest cooler point of ‘cooling airflow’. It’s drawn over cooler component parts, where the compressed air is then cooler to leave at the highest point, as in a chimney effect.

Intake air gets filtered in at the coolest part of the cabinet. This results in air being optimised for volumetric efficacy. With this, compressed air pressure can be varied according to requirements.

Motors, cabinets, and all electrical components are prone to overheating, if not positioned where the cooler intake air can be filtered in. Due to intelligent design, in BOGE screw air compressors, heat losses are not a problem, and working temperatures of componentry, motors, and cabinets remain cool and stable, either in load or idle operations.

BOGE engineers considered this principle in their designs and positioned the oil pre-separator at the lowest point of the air compressor system. Due to the rapid reduction of compressed air, any bulk oil ‘rains’ into a reservoir below, which is the most efficient way of separating the oil.

With the BOGE oil separation system, you can minimise pressure losses and ensure a residual content of 1-3 mg/m in every operating phase. This horizontal combi tank ensures low foam levels at load reversal, which virtually eliminates the risk for bulk oils reaching cartridges too!

BOGE oil separator cartridges give you a longer service life – due to the efficiency of the oil pre-separation effect, and because of the large safety distance between the oil surface and the separator. This prevents the oil from migrating into the separator cartridge and components.

Compact BOGE screw compressors have been known for their reliability in production for many years. The revolutionised and expanded C-2 series lives up to this reputation more than ever – with increased efficiency, greater flexibility and perfect ergonomics, as well as noticeably lower noise emissions and much easier maintenance. Your compressed air station can be tailored exactly to your needs – individually configured, yet uniformly compact.

Ergonomic control

The compressor control is positioned – depending on the configuration – on the front plate (on receiver machines) or tilted upwards (on stand-alone machines) to ensure the most ergonomic operation at all times.

Frequency-regulated fan

Frequency control is particularly recommended for fans in the partial load operational range and at low ambient temperatures because it considerably reduces both noise and power consumption. Available as an option from 11 kW.

Integrated dryer

An optional refrigerant dryer can be integrated in the housing of all models of the C-2 series. This makes entire compressed air stations possible even in the smallest of spaces, and you can always keep an eye on the visible dew point display.

Frequency-controlled with direct drive

Frequency control is recommended as it gives you the flexibility to adjust the free air delivery to individual requirements at any time. On all C-2 models, this option is combined with direct coupling to achieve new levels of efficiency.

Effective sound insulation

All models boast the standard sound insultation hood, which successfully keeps operating noise and vibrations to a minimum. The optional super sound insulation reduces the noise level even further, making it perfect for flexible installation.

Optional heat recovery

BOGE Duotherm offers huge potential for savings: up to 72 percent of the energy used to operate the compressor can be recovered and used for other applications – for example, space heating, domestic water heating or as process water heating.

Efficiency-optimised airend

An optimised screw profile and the compact design of the airend mean increased free air delivery with minimal power consumption. The C-2 guarantees the perfect airend for every performance class.

Elastic "SilentMount" suspension

An effective way of isolating vibrations, which consequently also lowers the noise level, is to attach the drive motor and the airend elastically to the base frame.

Type your best E-mail Address